Our service areas:

Our specialists have designed, introduced and mastered the following basic technologies:

- ceramic die packaging performed on cutting-edge innovative precise equipment of top world brands.

- wafer production of custom-designed dice manufactured using 2-micron process node.

- high-temperature bonding as well as chemical and electrochemical treatment solutions.

RF transistor packaging

Assembly of transistors and transistor-based complex devices.

Manufacturing of ceramic packages for bipolar, DMOS- and LDMOS- transistors. Our company designed 11 types of ceramic packages and started their mass production.

IC assembly line

Our quality management system is certified according to GOST R ISO 9001-2015 and GOST RV 0015-002-2020 (Russian standards).

Our plant has around 700 m2 class 10000 clean room area (7 ISO according to GOST R ISO 14644-1-2017 (Russian standard). Product yield is above 85,0 (assembly + testing).

Our assembly production line includes 44 items of equipment, 26 key pieces of which are of 2012-2020 years of manufacture. Engineering and technical facilities allow us to introduce over 10 new IC types per year.

Automated assembly technology allows us to process silicon wafers of up to 200 mm in diameter and perform IC packaging in all types of ceramic packages.

Package type | Number of pins |

CQFP (Ceramic Quad Flat Pack) | 8-256 |

CPGA (Ceramic Pin Grid Array) | 68-624 |

CBGA (Ceramic Ball Grid Array) | 68-675 |

CCGA (Ceramic Column Grid Array) | Up to 1800 |

DIP (Dual Inline Package) | 8-64 |

CLCC (Ceramic Leaded Chip Carrier) | 8-64 |

LCC (Leadless Chip Carrier) | 5-100 |

Our existing scientific and technical background in the development and implementation of microelectronic assembly technologies has made it possible to master and implement the following basic technologies:

Equipment: DISCO equipment set, Falcon S20PD automatic optical wafer inspection equipment.

Technical characteristics:

- up to 200 mm wafer diameter;

- TAIKO technology of ultra-thin wafer dicing ;

- wafer thickness from 100 µm to 680 µm +/-20 µm;

- scribe line width – 100 µm (80 µm min);

- die sizes: from 0,4 х 0,4 to 20,0 х 20,0 mm.

Equipment: TRESKY T-6000 and Datacon 2200 evoPLUS automatic bonding systems, Sonoscan Gen 6 ultrasound microscope.

Technical characteristics:

- die placement accuracy +/-5 µm;

- die sizes: from 0,4 х 0,4 to 15,0 х 15,0mm;

- conductive and nonconductive adhesives;

- bond seam quality control by ultrasonic scanning.

Equipment: BONDGET BJ-820, Delvotek 64000 G5, BONDGET BJ-939 bonding machines, DAGE 4000 PXY testing device.

Technical characteristics:

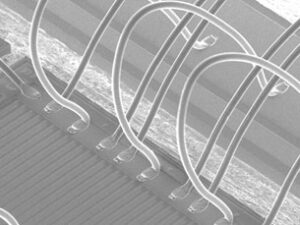

-bonding method: ultrasonic bonding (wedge-wedge), thermocompression bonding (wedge-wedge, ball-wedge);

- wire material: Al, Au, Pt;

- wire diameter: from 20 to 700 µm;

- min. dimensions of bond pads: 60 х 70 µm;

- number of levels: 3-4 levels;

- number of fuses: up to 10000 (determined by device design);

- bonding accuracy: +/- 3 µm;

- integrated bonding quality control system.

Equipment: Seam sealing system AF1250 in MX2000 environmental chamber, Pyramid HPS 9206M combo sealing complex, UL 1000 leak detector, WEB6000 gross helium leak hermeticity control system.

Technical characteristics:

- Hermetic seam welding of ceramic packages in nitrogen environment with ≥65 ºС controlled dew point -;

- helium leak control gauged to 6,65×10-3Pа•sm-3/s equivalent normalized helium leakage flow;

- gross helium leak control.

Currently, technologies like System in Package (SiP) are being implemented.

Equipment: SET FC-150

Technical characteristics:

- stacking of 2 to 6 dies in a chip:

- «chip-on-chip» (CoC), «chip-on-wafer» (CoW) and «chip-on-board» packaging technologies;

- die placement accuracy +/-1 µm;

- die sizes: from 0,4 х 0,4 to 15,0 х 15,0mm;

- bond pad pitch: 90, 100,120 µm;

- ball/bump material: Cu + SnAg (solder cap); Au; SnAgCu; PbSn

- ball/bump sizes: height from 14 to 100 µm; diameter from 25 to 100 µm ;

- ball/bump sizes: diameter from 100 to 600 µm.

Equipment: PacTech SB2-Jet

Technical characteristics:

- solder ball attachment to bond pads on dice, substrates and wafers (up to 300 mm diameter)

- bond pad pitch: 60, 90,100,120 µm;

- ball material: Cu + SnAg (solder cap); Au; SnAgCu; PbSn;

- ball sizes: height from 15 to 100 µm; diameter from 80 to 100 µm;

- ball sizes: diameter from 100 to 760 µm.

Equipment: Spectrum S-820

Technical characteristics:

- underfilling flip chips with compound material;

- 10 µm underfill volume;

- «chip-on-board» encapsulation.

Equipment: VLO 20

Technical characteristics:

- controlled soldering profile (5 thermocouples);

- max. temperature up to 450 ºС;

- vacuum soldering with formic acid vapor.

Assembly of RF, bipolar, DMOS-, LDMOS-, GaN-transistors

СВЧ-транзисторы выпускаются в корпусах:

Package types (RF) | Can be compared with: |

КТ-4-2 | M137 (Microsemi), TO-60 (Freescale) |

КТ-44 | SOT324B (Ampleon), M156 (Microsemi), 395B-01 (Freescale) |

КТ-45 | SOT161A (Ampleon), 368-03 (Freescale) |

КТ-56 | 55JU (Microsemi), 333-04 (Freescale) |

КТ-81 | SOT324B (Ampleon), 395B-01 (Freescale) |

КТ-82 | 55KV (Microsemi) |

КТ-83 | - |

КТ-83А | - |

КТ-81С | SOT1227A (Ampleon), Style101 440166 (MACOM) |

КТ-55С-1 | SOT504A (Ampleon), SOT467C (Ampleon), 440095 (MACOM) |

КТ-103А-1 | SOT540A (Ampleon), SOT539AN (Ampleon), 375G-04 (Freescale) |

КТ-103А-2 | SOT539AN (Ampleon) |

КТ-102-1 | 368-03 (Freescale) |

КТ-57А-1 | - |

МК КТ-81А-2 | SOT502 (Ampleon) |

МК КТ-55С-3 | SOT504A (Ampleon), SOT467C (Ampleon), 440095 (MACOM) |

МК КТ-81С-2 | SOT1227A (Ampleon), Style101 440166 (MACOM) |

МК КТ-127-1 | IBK (Sumitomo) |

МК КТ-52А-1 | WF (Eudyna) |

МК КТ-44D-1 | Integra IB1261 transistor package |

МК КТ-81D-3 | Integra IB1191 transistor package |

Our existing scientific and technical experience in microelectronic design and assembling process has made it possible for to master and implement the following technologies:

Equipment:

- Gamma-188 testing machine

- EM-6520 bed-of-nails system.

Technical characteristics of the process

Key parameters measured include:

- drain to source initial current;

- drain to source remaining current;

- threshold voltage;

- drain to gate max. permissible DC voltage

Equipment:

- UMP-1 semiconductor wafer mounting systems

- EM-2075 semiconductor wafer dicing system

- EM-3027 semiconductor wafer cleaning system

- Chip picking system

Technical characteristics of the process:

- wafer diameter up to 200 mm;

- TAIKO dicing technology for ultra-thin wafers;

- wafer thickness of 100 µm to 680 µm.

- min. scribe line (kerf) width – 80 µm.

Equipment:

- Semi-automatic EM-UP-5М system

- Semi-automatic PP-5 system

- Semi-automatic TRESKY T-3202 system

- Automatic Palomar 3500 system

- Automatic Palomar 3800 system

- Automatic Palomar 3880 system

Technical characteristics of the process:

- automatic eutectic die bonding forming Au-Si (Gold-Silicon) alloy;

- bonding accuracy ± 5 µm.

- bonding up to 12 dies in a package.

Equipment:

Automatic Palomar 3880 system

Technical characteristics of the process:

- GaN-on- SiC die bonding with the help of Au-based alloys providing necessary thermal profile.

Equipment:

- Delvotec 5630 ultrasonic bonding system

- Delvotec 5632 ultrasonic deep-access bonding system

- Delvotec G5 high-capacity ultrasonic bonding system

- Delvotec G5DA high-capacity ultrasonic deep-access bonding system

Technical characteristics of the process:

- automatic bonding of internal conductive wires with the possibility of forming stiches of the required shape using ultrasonic and thermosonic bonding methods.

- bonding with aluminum and golden wire of 17-75 µm in diameter.

- bonding accuracy 3 µm at 3σ.

- automatic control of the bonding process on-line.

Equipment:

- «Termopro» hot bench;

- ITS-500 semi-automatic sealer;

- SNOL 60/300 electric oven;

- MSH Press 6;

- Inficon UL-1000 leak tester

- Trio-tech G-254A gross leak bubble tester

Technical characteristics of the process:

- hermetic sealing of RF transistor in ceramic packages with PEK-30 adhesive (project of NIIET).

- hermetic sealing of RF transistor in ceramic packages using caps with glue.

Equipment:

- FMark-20 RL laser marking system

Technical characteristics of the process:

- ytterbium fiber laser.

- marking area 110х110 mm.

- marking speed from 1 to 4500 mm/sec.

- marking resolution - 40 µm.